Understanding Infusion Resins

What are Infusion Resins?

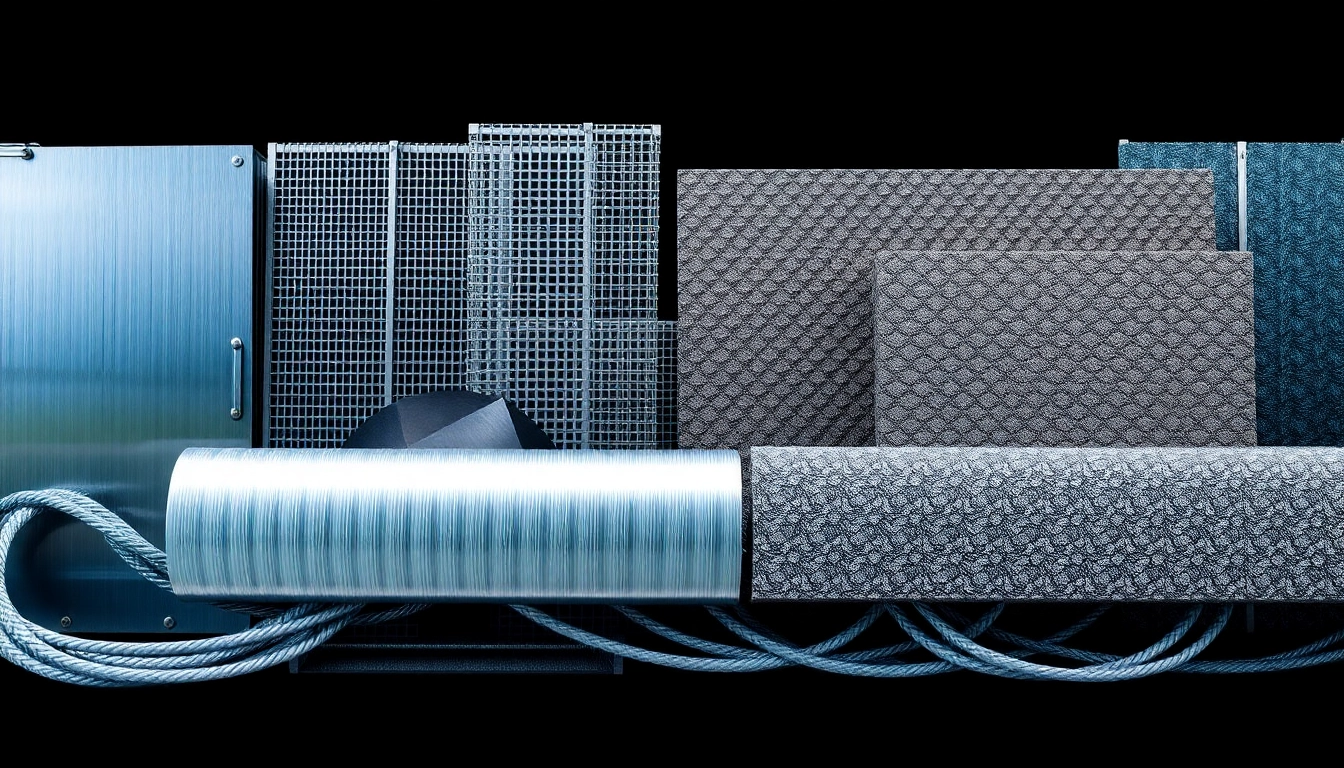

Infusion resins are specialized materials used in advanced composite manufacturing to create strong, lightweight structures. These resins are typically polymer-based and are designed to be low-viscosity, allowing them to flow smoothly into dry fibers under vacuum. By employing a technique known as resin infusion or vacuum infusion, manufacturers can achieve high fiber-to-resin ratios, resulting in components that exhibit superior strength and durability.

The infusion process involves placing dry reinforcement materials into a mold and then using a vacuum to draw the infusion resin into the mold. This method not only enhances the mechanical properties of the final product but also minimizes the risk of air entrapment, which can lead to defects such as voids and bubbles. Infusion resins are thus pivotal in producing high-performance composite parts used in various industries.

Benefits of Using Infusion Resins

The use of infusion resins offers several advantages that make them a preferred choice for composite manufacturing:

- Enhanced Strength-to-Weight Ratio: Infusion resins allow for the creation of parts that have significantly high strength while remaining lightweight. This is crucial in industries like aerospace and automotive, where performance and efficiency are paramount.

- Improved Surface Finish: The vacuum infusion process often results in a smoother surface finish compared to traditional methods, reducing the need for secondary finishing operations.

- Minimized Waste: The controlled flow of resin in infusion processes reduces excess material use, making it a more economical choice.

- Better Control Over Properties: Manufacturers can tailor the infusion resin formulations to achieve specific material properties, such as flexibility, hardness, and thermal resistance.

Common Applications of Infusion Resins

Infusion resins are utilized in a variety of applications across numerous sectors, including:

- Aerospace Components: Aircraft parts such as wing structures and fuselage sections benefit from the lightweight and high-strength properties of infusion resins.

- Marine Applications: Boat hulls and interior components are often created using infusion resins, providing durability and resistance to harsh marine environments.

- Automotive Parts: Components like body panels and structural elements increasingly use infusion resins to achieve weight savings and performance enhancements.

- Sports Equipment: High-performance gear, such as bicycles and surfboards, often employs infusion resins to improve strength without adding excessive weight.

Types of Infusion Resins

Low-Viscosity Infusion Resins

Low-viscosity infusion resins are designed to flow easily into complex part geometries, ensuring thorough wetting of the fiber reinforcement. The lower viscosity allows for quick and even resin distribution, granting manufacturers the ability to infuse larger and more intricate parts with minimal effort.

Moreover, low-viscosity resins contribute to better fiber wetting, which in turn enhances mechanical properties. This is particularly useful when working with high-density fabrics or multi-layered composites.

Epoxy vs. Polyester Infusion Resins

When selecting infusion resins, manufacturers often debate between epoxy and polyester systems. Each type has distinct advantages:

- Epoxy Resins: These resins are known for their superior adhesion, chemical resistance, and overall mechanical properties. They are ideal for applications requiring high durability and performance, making them suitable for aerospace and marine environments.

- Polyester Resins: While generally less expensive than epoxies, polyester resins may lack some of the performance characteristics viewed as critical in more demanding applications. They tend to cure faster, which can enhance manufacturing efficiency but may also lead to issues such as shrinkage and reduced strength under certain conditions.

Eco-Friendly Options for Infusion Resins

With growing concerns over sustainability, manufacturers are increasingly looking for eco-friendly infusion resin alternatives. Bio-based resins made from renewable resources, such as vegetable oils, provide a more sustainable option without compromising performance. These resins can meet the needs of environmentally conscious manufacturers, allowing for lower carbon footprints while still delivering impressive mechanical properties.

Best Practices for Using Infusion Resins

Preparation Before Using Infusion Resins

Proper preparation is essential for a successful infusion process. Key steps include:

- Mold Preparation: Ensure the mold is clean, dry, and properly coated with a release agent to facilitate easy part removal post-curing.

- Material Selection: Choose appropriate fiber reinforcements that pair well with the selected infusion resin for optimal performance.

- Vacuum System Setup: Utilize an efficient vacuum system to create a suitable working environment, as any fluctuations can affect resin flow and curing.

Application Techniques for Infusion Resins

Effective application techniques can enhance the quality of the final product. The most essential techniques include:

- Layering: Utilize multiple layers of fiber reinforcement and resin to ensure complete saturation and strength.

- Controlled Flow: Implement a controlled method of introducing resin into the mold, such as staggered infusion points, to prevent premature curing and guarantees thorough wetting.

- Monitoring: Regularly check the vacuum levels throughout the process to ensure consistent pressure is maintained.

Post-Application Care and Curing

After application, it’s critical to monitor the curing process:

- Curing Conditions: Follow the manufacturer’s recommended temperature and humidity for optimal curing.

- Completion Checks: Assess the part for any defects, such as bubbles or uneven surfaces, that may need to be corrected before finalizing.

- Finishing Touches: Once cured, consider additional finishing techniques, such as sanding or polishing, to improve surface quality and aesthetics.

Performance Metrics for Infusion Resins

Evaluating Strength and Clarity

The performance of infusion resins is often evaluated based on their mechanical properties, including tensile strength, flexural strength, and impact resistance. These metrics determine how well a final composite part can withstand various loads and stresses in real-world applications. Clarity is also an important aspect, especially for aesthetic components.

Controlling Flow and Viscosity

Monitoring and controlling the flow and viscosity of the infusion resin is crucial for achieving quality outcomes. A viscosity that is too high may result in incomplete saturation of the fibers, while too low a viscosity could lead to excess resin and compromise structural integrity. The right balance is vital for effective results.

Assessing Durability and Sustainability

The durability of infusion resins can be assessed by analyzing factors such as chemical resistance, thermal stability, and environmental impact. Sustainable practices, including the use of eco-friendly materials and minimizing waste during the manufacturing process, are also a critical part of modern resin assessment.

Future Trends in Infusion Resins

Technological Innovations in Infusion Resins

The future of infusion resins is being shaped by technological advancements, with innovations improving the properties and applications of resins. Developments in automation, for example, are making the infusion process more efficient, while advanced material science continues to enhance resin formulations.

Sustainability Practices in Resin Production

As environmental concerns rise, there is an increasing push for the adoption of sustainable practices in resin production. This includes utilizing renewable resources, reducing waste, and recycling end-of-life composites. Industry collaboration to implement sustainability standards is becoming a priority.

Market Growth and Industry Insights

The global market for infusion resins is experiencing significant growth, driven by advancements in manufacturing techniques and an increasing demand for lightweight composites across various industries. Companies are investing in research and development to create high-performance, sustainable materials that meet the evolving needs of the market.