The Importance of Selecting the Right Tape Manufacturer

When it comes to securing materials or projects, the type of tape used can make a significant difference. Selecting the right tape manufacturer can affect not only the durability and functionality of the adhesive products but also your entire workflow. With so many options available, making an informed choice becomes paramount to ensure you receive a product that meets your specific needs reliably.

Understanding Your Adhesive Needs

Different applications require different types of adhesives. Understanding your adhesive needs is the first step in selecting a manufacturer. For instance, if you are in construction, you may require duct tape that can withstand weather elements, whereas in medical settings, sterile tapes are a must. Enumerating your specific requirements helps narrow down potential manufacturers who specialize in your necessary tape applications.

Quality Standards in Tape Production

Quality assurance in tape production cannot be overlooked. The International Organization for Standardization (ISO) provides specific standards that adhesive tape manufacturers must follow. These standards help ensure product consistency, reliability, and safety. When selecting a manufacturer, confirm that they adhere to quality certifications relevant to your industry. This process may involve reviewing their lab results, customer feedback, and their manufacturing processes.

Evaluating Manufacturer Capabilities

Not all tape manufacturers have the same capabilities when it comes to customization, production volume, and technological resources. Evaluate whether the manufacturer can meet your orders promptly, especially if you’re operating within tight deadlines. Additionally, inquire about their innovation in tape technology, as this may provide you with the edge necessary in a competitive market.

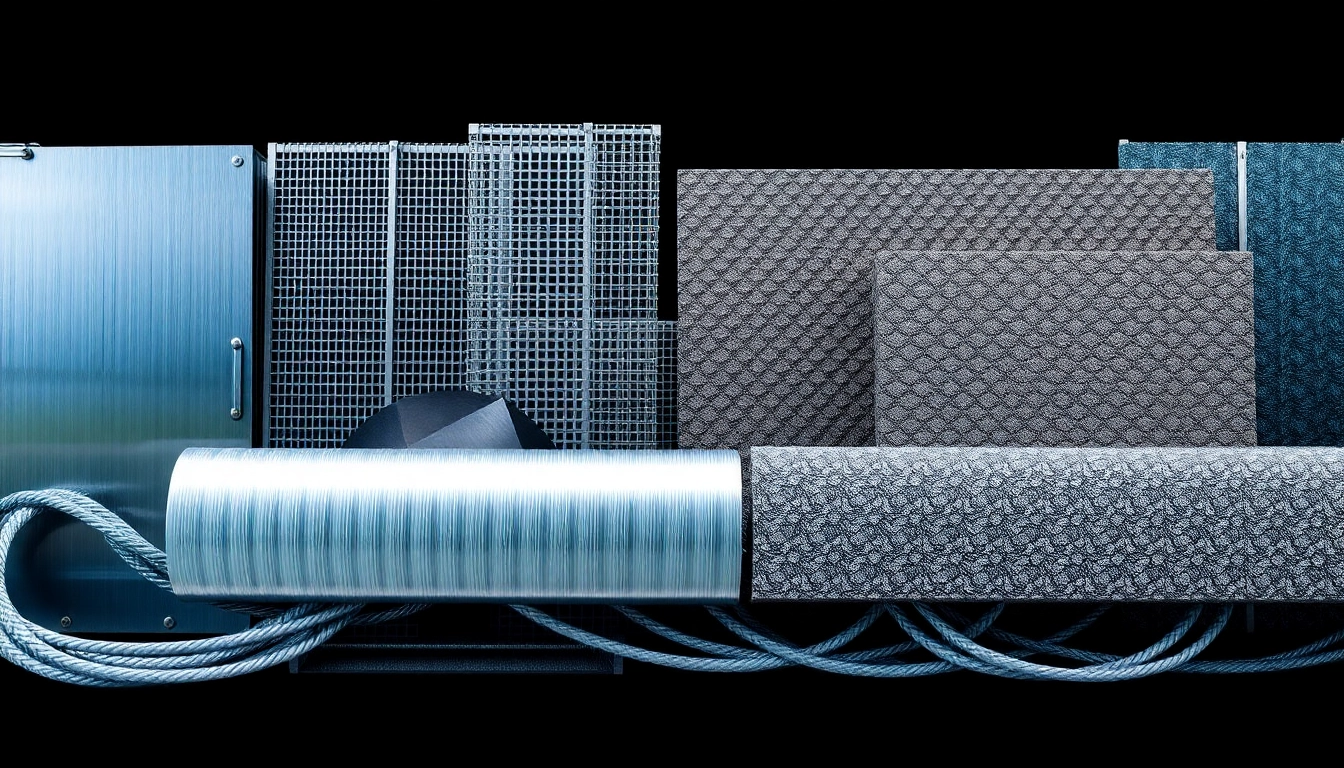

Types of Tapes Offered by a Tape Manufacturer

Understanding the various options available in the adhesive tape market can further assist in making an informed decision regarding a manufacturer. Key tape types include:

Adhesive Variants: Hot Melt, Acrylic, and Rubber

These are the three main categories of adhesive used in tape manufacturing, and choosing the right one depends on your application. Hot melt adhesives offer quick bonding capabilities, making them ideal for packaging. Acrylic adhesives are known for their durability and are often used in outdoor applications. Rubber-based adhesives are more flexible and better suited for applications that require lower-temperature performance.

Specialty Tapes for Unique Applications

Besides the standard tapes, specialty tapes are available for specific industry needs. These can include double-sided tapes, masking tapes, and tapes with non-staining adhesives. A good manufacturer will offer customized solutions that fit unusual application requirements, allowing for greater flexibility in project execution.

Environmental Considerations in Tape Production

As sustainability becomes increasingly important, the demand for eco-friendly adhesives is growing. Tape manufacturers are investing in biodegradable and recyclable materials, and it’s crucial to consider a manufacturer’s environmental policies. Assess whether they use green practices in their production processes, such as minimal waste generation and sustainable sourcing of raw materials.

Assessing Service Offerings from a Tape Manufacturer

The relationship with a tape manufacturer goes beyond simply purchasing a product. A reliable manufacturer will also offer a range of services that can enhance your experience.

Custom Tape Solutions for Business Needs

Many businesses require unique solutions that off-the-shelf products cannot meet. Custom tape solutions involve modifying existing products or developing new solutions tailored to specific needs. This can involve size adjustments, specific adhesive types, or even printing custom designs on the tape for branding purposes.

Technical Support and Consultation Services

Choosing a manufacturer that provides technical support can save significant time and resources. This can include consultation services to help determine the right products for your needs, as well as troubleshooting any issues you may encounter during use. A manufacturer with a solid support system can enhance operational productivity.

Delivery and Logistics: Getting Tapes to You

Effective logistical planning is crucial for businesses that operate with just-in-time inventory strategies. Evaluate how manufacturers manage delivery timelines and whether they can adapt to changes in your order volume or schedule real-time updates regarding shipping and delivery. Transparent communication in logistics can prevent interruptions in your project workflows.

The Role of Technology in Tape Manufacturing

The integration of technological advancements has transformed tape manufacturing. Understanding these advancements can help business owners select the right partners for their adhesive needs.

Innovations in Adhesive Technology

From improved heat resistance to enhanced bonding capabilities, innovations in adhesive technology lead to better performance across various applications. Manufacturers investing in R&D on new formulations are creating products that tackle existing challenges, providing greater efficiencies and adhering better under strenuous conditions.

Automated Production Processes

Automation in manufacturing not only increases production speeds but also enhances precision. Evaluate whether your prospective tape manufacturer utilizes cutting-edge machinery that can improve production quality. Automation can reduce human error and waste, leading to more consistent product offerings.

Quality Control Measures in Manufacturing

Robust quality control measures are essential to ensure that tape products perform as expected. A reliable manufacturer should have implemented rigorous testing protocols at each stage of production, from raw material sourcing to final product shipment. Conducting tests like peel adhesion, tensile strength, and environmental impact assessments ensures that the tape meets the required performance metrics.

Future Trends for Tape Manufacturers

The adhesive industry continues to evolve, driven by market demands and technological innovations. Awareness of these trends can provide valuable insights when assessing future tape partners.

Market Adaptations and Consumer Demands

Consumer preferences continue to drive manufacturers to adapt their product offerings. There’s an increasing demand for specialized adhesives in various sectors, including automotive, electronics, and medical fields. Manufacturers that stay ahead of these trends will likely thrive, which is a crucial consideration for businesses looking for long-term partnerships.

Sustainability Practices in the Industry

The push for sustainability is not just a consumer trend; it is quickly becoming an industry standard. Tape manufacturers who adapt eco-friendly practices in their production processes are not only meeting regulations but also appealing to environmentally conscious customers. This includes implementing sustainable manufacturing processes and using recyclable materials wherever possible.

Research and Development for New Tape Products

Investing in R&D allows tape manufacturers to innovate and develop new products that meet the changing needs of industries. This includes researching alternative materials, new adhesive technologies, and smarter production methods. Organizations should look for manufacturers committed to continuous improvement and innovation in their offerings.