Introduction to Electromagnetic Shielding Materials

In today’s technologically driven world, the protection against electromagnetic interference (EMI) is paramount for ensuring the functionality and reliability of electronic devices. Electromagnetic shielding materials play a crucial role in mitigating unwanted electromagnetic signals that can disrupt performance, diminish quality, and even endanger safety in various applications. This article endeavors to delve into the fundamental aspects of EMI shielding materials, exploring their types, properties, performance metrics, and future trends.

What are Electromagnetic Shielding Materials?

Electromagnetic shielding materials are substances designed to protect electronic devices and systems from electromagnetic fields. These materials either absorb or reflect electromagnetic waves, preventing them from interfering with sensitive equipment. They are essential in numerous applications, including telecommunications, medical devices, industrial automation, and consumer electronics. The effectiveness of shielding can depend on the frequency of the electromagnetic wave, the material used, and the design of the shielding structure.

Importance in Modern Applications

As society increasingly relies on wireless communications and electronic devices, the risk of EMI interference grows. For instance, in the medical field, EMI can pose significant risks to the functionality of critical equipment, such as MRI machines or pacemakers, potentially endangering patient health. Similarly, in industrial settings, equipment can be damaged or fail if subjected to unexpected electromagnetic interference. Thus, effective EMI shielding is not only a technical necessity but also an essential component of safety protocols.

Common Challenges in EMI Prevention

Despite the advancements in materials technology, several challenges persist in EMI prevention. One prominent issue is the trade-off between shielding effectiveness and weight or flexibility. For applications that require lightweight and flexible materials, such as aerospace and portable devices, achieving sufficient shielding can be particularly challenging. Additionally, there are cost implications, as high-performance shielding materials may incur significant manufacturing costs. This necessitates ongoing research and development to balance performance, weight, and cost considerations.

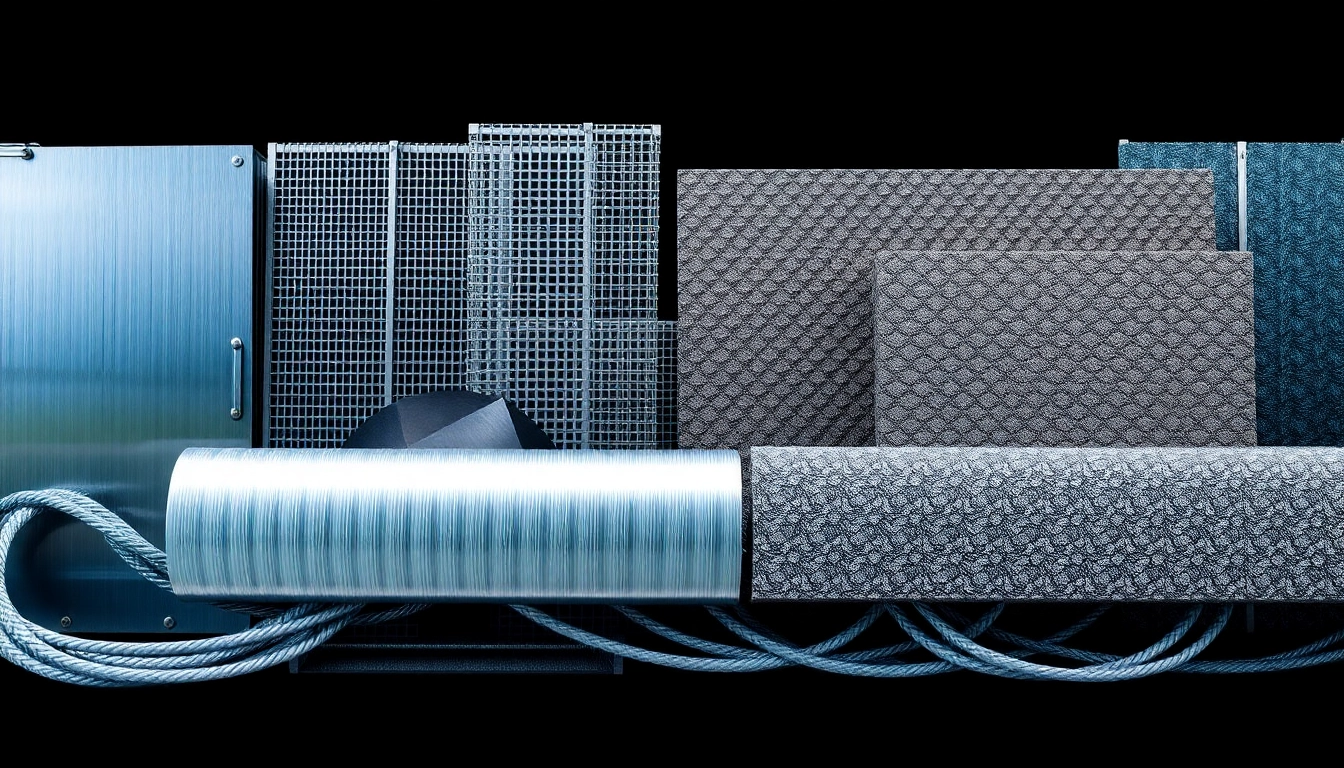

Types of Electromagnetic Shielding Materials

Metals: The Backbone of Shielding

Metals are the most common materials used for effective electromagnetic shielding due to their high electrical conductivity. Copper, aluminum, and steel are among the most frequently utilized metals in shielding applications:

- Copper: Known for excellent conductivity, it is particularly effective at reducing both magnetic and electric fields. Copper is widely used in the construction of EMI shielding enclosures and cables.

- Aluminum: Lightweight and cost-effective, aluminum offers good shielding efficiency and is often preferred for applications requiring flexible materials.

- Steel: While heavier than aluminum, steel’s considerable strength and durability make it ideal for structural applications.

- Nickel and Silver: These metals are commonly used for specialized applications requiring corrosion resistance and enhanced shielding.

Non-Metallic Options: Innovations in EMI Shielding

Besides metals, a variety of non-metallic materials have emerged as viable options for electromagnetic shielding. These include:

- Conductive Polymers: Offering flexibility and lightweight characteristics, conductive polymers are an innovative solution for applications where conventional metals may be too heavy.

- Composite Materials: These involve the combination of conductive and non-conductive materials, offering tailored properties for specific applications.

- Cement and Ceramics: New developments in composite materials have led to the creation of cement-based and ceramic-based shielding options that are particularly effective for large-scale installations.

Review of Hybrid Materials

Hybrid materials combine properties from both metallic and non-metallic options, leveraging the strengths of each to overcome the limitations of traditional shielding materials. These innovative materials often provide enhanced mechanical durability, flexibility, and performance across a broad frequency spectrum. Research into nanocomposites and 3D printing technologies is pushing the boundaries of hybrid material applications, opening doors for new shielding possibilities.

Properties and Performance Metrics

Key Properties of Effective Shielding

Understanding the key properties of effective electromagnetic shielding materials is crucial for selecting the right option for a specific application. The essential properties include:

- Shielding Effectiveness: Measured in decibels (dB), this indicates how well a material can attenuate electromagnetic waves. Higher values signify better shielding performance.

- Thickness: Generally, thicker materials provide better shielding; however, this may not always be practical due to weight and space constraints.

- Frequency Response: Different materials perform uniquely across various frequencies, so it’s critical to consider the range of frequencies of interest in specific applications.

- Durability and Corrosion Resistance: Materials must withstand their operational environment, including exposure to moisture, chemicals, and physical wear over time.

Testing Methods for EMI Shielding

To evaluate the performance of electromagnetic shielding materials, various testing methods are utilized. Common techniques include:

- Transmission Loss Measurements: This method assesses how much electromagnetic energy is lost as it passes through a shielded material.

- SAR Testing (Specific Absorption Rate): Used to evaluate body-worn devices, measuring how much electromagnetic energy is absorbed by body tissues.

- Chamber Testing: Uses anechoic chambers to accurately measure the effectiveness of shielding against various sources of electromagnetic emissions.

Comparative Analysis of Material Performance

Various electromagnetic shielding materials exhibit different performance characteristics based on their composition and structure. Comparative analysis often leads to making informed decisions regarding material selection:

- Copper vs. Aluminum: Copper generally demonstrates superior shielding effectiveness but can be heavier and more expensive compared to aluminum, which offers a good trade-off for lightweight applications.

- Conductive Polymers vs. Metals: Conductive polymers, while flexible, may not achieve the same levels of attenuation as pure metals but excel in applications where weight is critical.

- Hybrid Materials Analysis: Emerging hybrid materials can optimize both frequency response and shielding effectiveness, leading to innovative solutions for complex challenges.

Applications of Electromagnetic Shielding

Consumer Electronics and Multimedia

In consumer electronics, effectively managing EMI is crucial for device performance. Computers, smartphones, and other multimedia products increasingly incorporate shielding solutions to prevent interference that can affect sound and image quality. Shielding enclosures, wires, and circuits must be designed to avoid both cross-talk between components and external interference from RF sources.

Medical Equipment Shielding

In the medical field, electromagnetic shielding is critical to ensure the reliability of sensitive equipment such as MRI machines, CT scanners, and monitoring devices. Given the potential risks associated with EMI to patient health and device accuracy, stringent regulations govern the use of shielding materials in medical settings. Effective shielding can lead to optimized imaging results and patient safety.

Industrial and Commercial Uses

Industries utilizing large machinery or operating in electromagnetic-sensitive environments often require robust shielding solutions. Manufacturing equipment, assembly lines, and larger commercial applications utilize shielding to enhance productivity and safety. Examples include shielding of control cabinets, data centers, and automotive components to manage EMI effectively and ensure compliance with industry standards.

Future Trends and Developments in Shielding Materials

Emerging Technologies in Materials Science

The continuous evolution in materials science is paving the way for groundbreaking developments in electromagnetic shielding. Innovations in nanotechnology and material composites promise to enhance the effectiveness of shielding materials significantly. Research is focused on developing lightweight, flexible materials that maintain high conductivity while being cost-effective.

Sustainability and Eco-Friendly Materials

With a growing emphasis on sustainability, manufacturers are now exploring eco-friendly alternatives to conventional shielding materials. This includes biodegradable composites and recycled materials, alongside traditional options that can still meet performance specifications without compromising the environment.

Global Market Trends for Electromagnetic Shielding

The global market for electromagnetic shielding materials is expected to grow substantially, driven by the increasing adoption of smart technology, IoT devices, and stringent regulations across industries. Analyzing market trends will reveal shifting consumer preferences and emerging opportunities for manufacturers to innovate in the realm of EMI shielding.