What is Machine Vision?

Machine vision refers to the technology and methods that allow machines to interpret visual information, primarily through image capture and analysis. This technology is fundamentally reshaping how industries perform inspections, automate processes, and enhance productivity. By utilizing cameras, software algorithms, and sometimes sophisticated processing hardware, machine vision systems can recognize patterns, detect anomalies, and guide actions in real time. As industries strive for efficiency and accuracy, understanding machine vision becomes increasingly essential.

Definition and Key Components

Machine vision can be defined as the application of computer vision principles to automated systems in industrial settings, enabling these systems to “see” and understand their environment. The main components of a typical machine vision setup include:

- Cameras: These capture images of the objects being inspected or monitored. Depending on the application, various types of cameras are used—ranging from standard 2D cameras to sophisticated 3D image capture systems.

- Lighting: Proper illumination is crucial for image capture. Different lighting techniques, such as backlighting and diffuse lighting, are employed based on the surfaces and materials being inspected.

- Processing Unit: This consists of software and sometimes hardware, such as GPUs, that perform complex image analyses, feature extraction, and decision-making processes.

- Interface: A user-friendly interface is necessary for operators to set parameters, monitor performance, and intervene when necessary.

How Machine Vision Works

The operation of machine vision systems can be broken down into several key stages:

- Image Acquisition: The first stage involves capturing images through cameras. This can occur in real-time or as a batch process.

- Image Preprocessing: Raw images may contain noise or artifacts. Preprocessing techniques, such as filtering and contrast adjustment, are applied to enhance image quality.

- Feature Extraction: Important features are identified and extracted from the images. This can include edges, shapes, colors, or patterns that are essential for analysis.

- Decision Making: The system uses algorithms, often powered by machine learning, to classify objects, detect defects, or guide machinery based on the features identified.

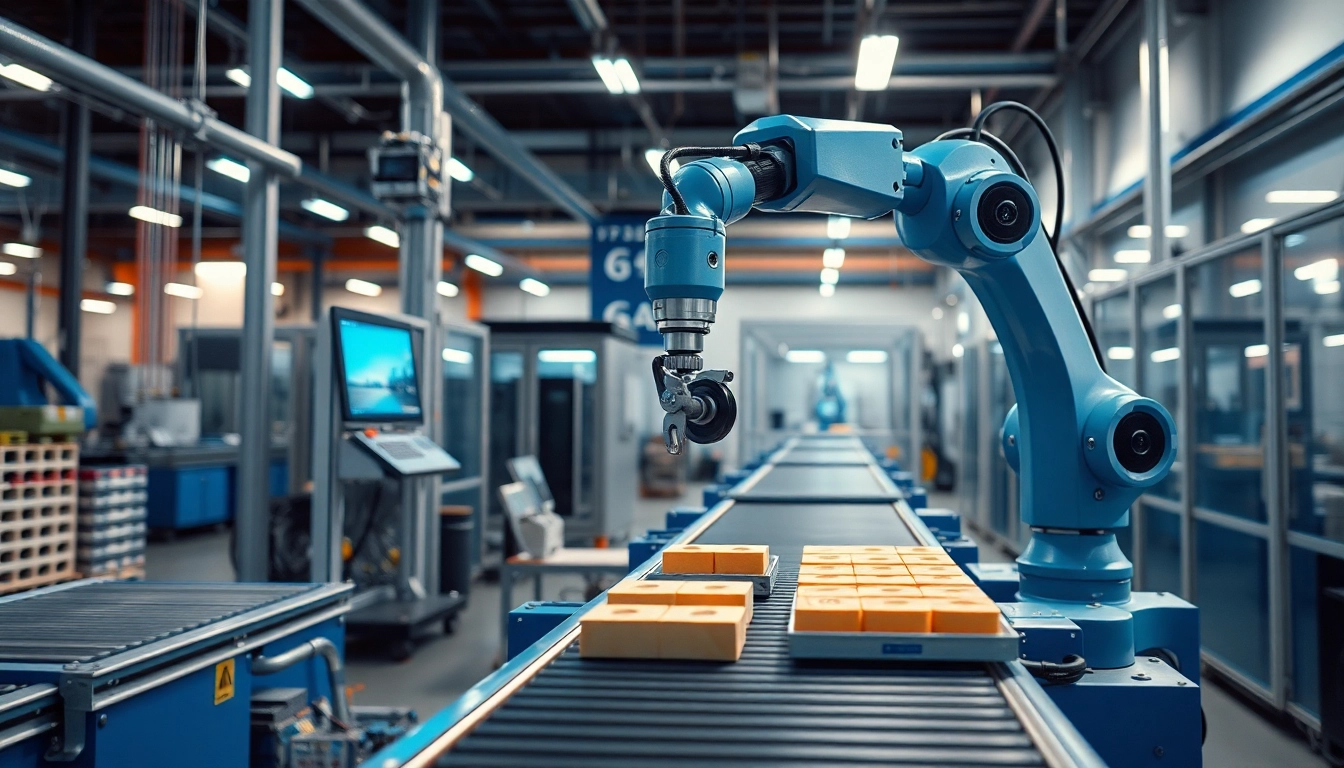

- Action Execution: Based on the decision-making results, the machine vision system can instruct mechanical systems (like robotic arms) to take specific actions, such as sorting products, signaling an error, or adjusting a manufacturing process.

Applications Across Industries

Machine vision has a wide array of applications across various sectors, all taking advantage of its ability to automate and enhance visual inspection processes. Here are some notable applications:

- Manufacturing: In manufacturing, machine vision systems are used for quality control, ensuring products meet specifications by automating inspections for defects or deviations in size and shape.

- Pharmaceuticals: Machine vision plays a critical role in ensuring the integrity and quality of drugs, through processes like verifying labels, checking for contaminants, and monitoring packaging.

- Transportation: Automated vehicles and drones utilize machine vision for navigation and obstacle avoidance, enabling a level of autonomy that requires real-time processing of visual information.

- Food Processing: In the food industry, machine vision systems are employed to inspect product quality, monitor hygiene, and ensure compliance with health regulations.

- Logistics and Warehousing: Machine vision aids in the automation of sorting and order fulfillment processes, using barcode scanning and package inspection to streamline operations.

Benefits of Implementing Machine Vision

Integrating machine vision technology into business processes offers numerous benefits that contribute to overall efficiency and profitability. Here’s a closer look at the key advantages:

Quality Assurance and Defect Detection

Machine vision significantly enhances quality assurance by automating defect detection processes. Traditional manual inspections are prone to human error and can be time-consuming. Automated systems, on the other hand, provide consistent, high-speed inspection capabilities that improve detection rates. For instance, in a manufacturing setting, machine vision can identify defects that might be invisible to the naked eye, thereby ensuring higher product quality and compliance with safety standards.

Increased Operational Efficiency

With real-time data processing capabilities, machine vision streamlines operations and reduces cycle times. This translates into faster production rates and lower operational costs. For example, in a bottling plant, machine vision systems can rapidly check fills, identify misplaced labels, and ensure correct caps are applied—all of which enhance the speed at which products are prepared for distribution.

Cost-Effectiveness of Automation

While the upfront investment in machine vision technology may be substantial, the long-term savings it provides are considerable. Costs related to labor, human error, downtime due to inspections, and product recalls can all be significantly reduced. Moreover, by minimizing waste and improving yield rates, businesses can enhance their bottom lines.

Machine Vision vs. Computer Vision

Although often used interchangeably, machine vision and computer vision carry distinct meanings. Understanding their differences is vital for selecting the right solution for specific applications and industries.

Understanding the Differences

Machine vision specifically refers to automated systems used in manufacturing and industrial sectors. It typically emphasizes tasks such as quality control, error detection, and guiding machines based on visual input. In contrast, computer vision is more general and encompasses various fields, including machine learning and artificial intelligence, focusing on the ability of machines to interpret and understand the visual world in a broader context.

Use Cases for Each Technology

Machine vision is frequently employed in applications where speed and precision are crucial, such as in manufacturing lines for defect detection or barcode scanning. Computer vision, meanwhile, finds relevance in areas like image recognition, facial recognition in security systems, and even in healthcare for diagnosing conditions based on visual inputs.

Why Both Are Essential in Modern AI

As automation and AI technology continue to advance, both machine vision and computer vision play complementary roles. While machine vision contributes to operational efficiency and quality assurance in industrial processes, computer vision expands into new domains, enriching capabilities such as predictive analytics and behavioral analysis. Together, they create a robust framework for enhancing human efficiency and augmenting decision-making processes across diverse sectors.

Implementing Machine Vision in Your Business

For organizations looking to integrate machine vision technology, a systematic approach is essential. Here are the steps to consider:

Steps to Get Started with Machine Vision

The implementation process of machine vision can be segmented into the following steps:

- Needs Assessment: Identify the specific processes where machine vision could enhance performance and determine the return on investment.

- System Design: Collaborate with experts to design a system tailored to your business needs, considering factors like lighting, camera selection, and software requirements.

- Prototype Testing: Before full-scale implementation, develop prototypes to assess functionality and gather feedback from operators.

- Rollout and Training: Deploy the system while simultaneously conducting training sessions for employees to ensure smooth adoption.

- Monitoring and Feedback: Continuously monitor system performance and refine workflows based on user feedback and operational data.

Key Considerations for Successful Deployment

Several factors are critical to the success of machine vision deployment:

- Integration with Existing Systems: Ensure that new machine vision systems seamlessly integrate with your current equipment and IT infrastructure.

- Operator Training: Investing in training programs helps staff understand how to utilize the technology effectively and troubleshoot common issues.

- Maintenance and Updates: Regular system updates and maintenance are necessary to ensure continued performance and adaptation to new operational challenges.

Case Studies and Success Stories

While each organization’s journey with machine vision is unique, numerous success stories highlight the technology’s transformative potential:

- A Leading Automotive Manufacturer: Implemented a machine vision system for part inspections that reduced defect rates by 30%, significantly decreasing the costs associated with rework and scrap.

- A Global Food Processing Company: Adopted machine vision for packaging inspections, leading to a 50% reduction in inspection time and an increase in operational efficiency by 20%.

- Pharmaceutical Production Facility: Integrated vision systems to verify labels and packaging, which led to a noteworthy increase in compliance rates and a reduction of product recalls.

The Future of Machine Vision Technology

As machine vision continues to evolve, it remains crucial for businesses to stay ahead of trends impacting the technology’s development and application.

Trends to Watch in Machine Vision

Key trends shaping the future of machine vision include:

- AI and Deep Learning Integration: The incorporation of advanced algorithms allows for more sophisticated pattern recognition and decision-making capabilities.

- Enhanced Sensor Technology: Ongoing improvements in sensor performance, including higher resolutions and sensitivity to varying lighting conditions, contribute to better accuracy and speed.

- Accessibility of Machine Vision Solutions: As technology reduces in cost, machine vision becomes more accessible for small- and medium-sized enterprises, enabling broader industry adoption.

Innovations and Emerging Technologies

Emerging technologies such as 3D imaging, multispectral and hyperspectral imaging, and the Internet of Things (IoT) will further redefine machine vision capabilities. These innovations create opportunities for more accurate analyses, predictive maintenance, and smarter automation solutions.

The Impact on Job Markets and Workforce Skills

As organizations increasingly leverage machine vision technology, demands for a skilled workforce will rise. It will be essential for employees to adapt by acquiring skills in technology management, data analysis, and system integration. Educational institutions and organizations will need to collaborate to create training programs that address these skills gaps, ensuring the workforce is prepared to engage effectively with machine vision systems.